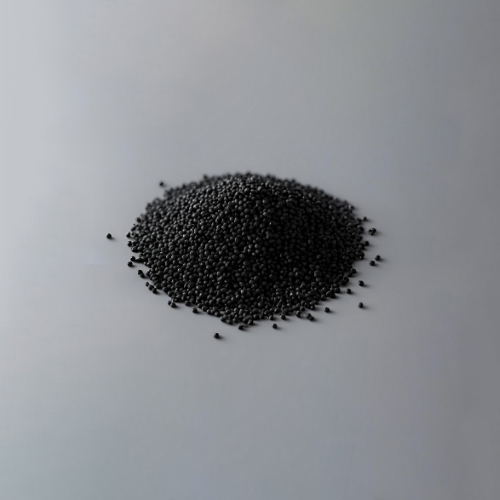

Plunger Lubrication Shot Beads

Product Details:

- Material Feature Plastic

- Grade Various Grades Available

- Color Different Available

- Warranty Yes

- Click to View more

Plunger Lubrication Shot Beads Price And Quantity

- 25 Kilograms

- 200.0 INR/Kilograms

Plunger Lubrication Shot Beads Product Specifications

- Plastic

- Different Available

- Yes

- Various Grades Available

Plunger Lubrication Shot Beads Trade Information

- [ ]

- 10000 Kilograms Per Month

- 3 Days

- No

- [ ]

Product Description

Shot Beads are specially formulated lubricants designed to reduce friction and wear in die-casting machines, ensuring smooth plunger movement and consistent casting performance. We offer four types of shot beads, each varying in wax content, quality, and price, to meet diverse operational needs.

Key Features:

- Fully consumed during the casting process, leaving no residue.

- Reduces wear on plunger tips and sleeves, extending their lifespan.

- Enhances injection speed and overall production efficiency.

- Provides a clean and eco-friendly lubrication solution.

FAQs of Plunger Lubrication Shot Beads Granules:

1. What are Shot Beads used for?

Shot Beads are used in die-casting machines to reduce friction between the plunger and sleeve, ensuring smooth movement and enhancing casting quality. They are fully consumed during the process, leaving no residue.

2. How do Shot Beads improve die-casting performance?

By minimizing friction and wear on plunger tips and sleeves, Shot Beads extend the lifespan of components, improve casting precision, and increase overall production efficiency.

3. How many types of Shot Beads are available?

We offer four types of Shot Beads, each differing in wax content, quality, and price, allowing you to choose the best option based on your specific operational needs and budget.

4. How do I choose the right Shot Beads for my process?

Choosing the right Shot Beads depends on factors like casting material, operating temperature, and budget. Our team will help you select the most suitable Shot Beads based on your specific requirements.

5. What are the advantages of using Shot Beads over traditional lubricants?

Shot Beads offer superior friction reduction, increased plunger lifespan, no smoke, and better casting quality compared to traditional lubricants, leading to improved efficiency and reduced downtime in die-casting operations.

6. How are Shot Beads applied?

Shot Beads are typically applied through an automated dispensing system, ensuring consistent and precise lubrication for optimal die-casting performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+